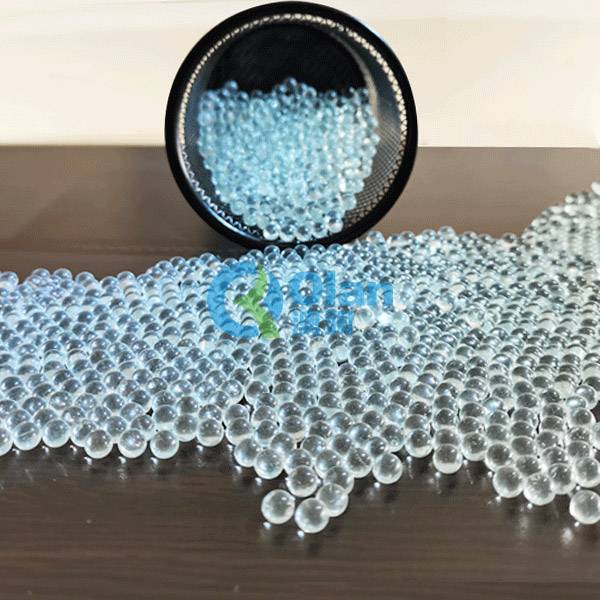

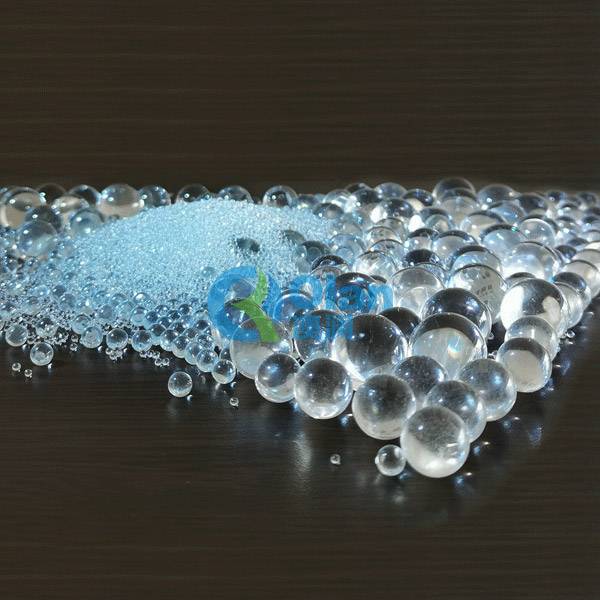

Glass Beads Used In Sandblasting Machine - Manufacturers, Factory, Suppliers from China

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Glass Beads Used In Sandblasting Machine, En1424, Cns 4342-1989, Road Marking Paint Glass Beads,Bs En 1423-1998. Competitive price with high quality and satisfying service make us earned more customers.we wish to work with you and seek common development. The product will supply to all over the world, such as Europe, America, Australia,Rio de Janeiro, Russia,Manila, Brasilia.Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

Related Products