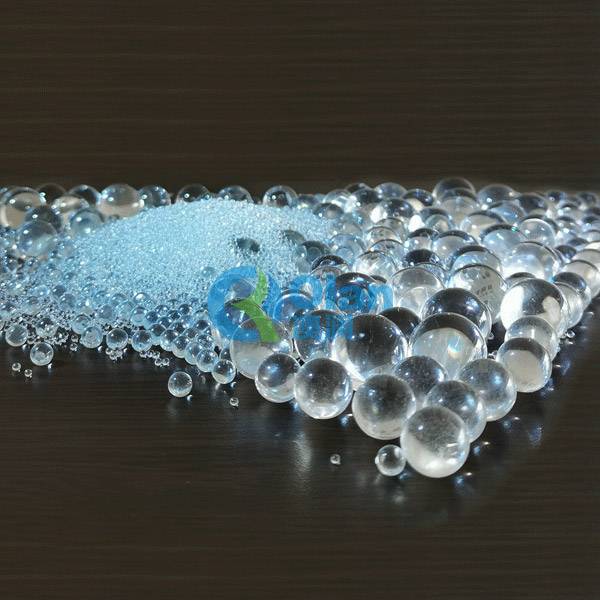

Glass Microspheres For Sandblasting - China Manufacturers, Factory, Suppliers

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for Glass Microspheres For Sandblasting, Sae J1173:1988 Glass Beads For Peening, Micro Glass Beads, Glass Beads Tj/T446-2001 Drop On For Road Marking,Glass Beads Aashto M247-2009. We are always looking forward to forming successful business relationships with new clients around the world. The product will supply to all over the world, such as Europe, America, Australia,Afghanistan, Norway,Iceland, Saudi Arabia.Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

Related Products