2020 High quality Hardness 6-7 Mohs Sandblasting Glass Beads - Sandblast Glass Beads 60# – OLAN

2020 High quality Hardness 6-7 Mohs Sandblasting Glass Beads - Sandblast Glass Beads 60# – OLAN Detail:

Product Function

Blasting with Glass Beads under pressure will maintain the products without dimensional change, without contamination and without overstressing. It produces a consistent metallurgical clean surface finish. Conventional Blasting Materials such as Aluminium Oxide, Sand, Steel Shots will either leave a Chemical Film on the blasted surface or have cutting action. Glass beads generally smaller and lighter than other media and can be used to peen into sharp radii of threads and delicate parts where very low intensities are required. Shot Blasting with the Glass Beads completely prepares metal surface for any type of coating on it such as painting, plating enameling or glass lining.Glass beads can be safe compared to other blast medias. Additional benefits of glass bead blasting include that you can use them for a few cycles before they no longer clean a surface. It is common for glass bead media to last 4 – 6 cycles before needing to be replaced. Finally, glass beads can be used in a suction or pressure blast cabinet. This makes it versatile and can help offer a blast cleaning media that keeps your blast cabinet costs down.

Technical Information

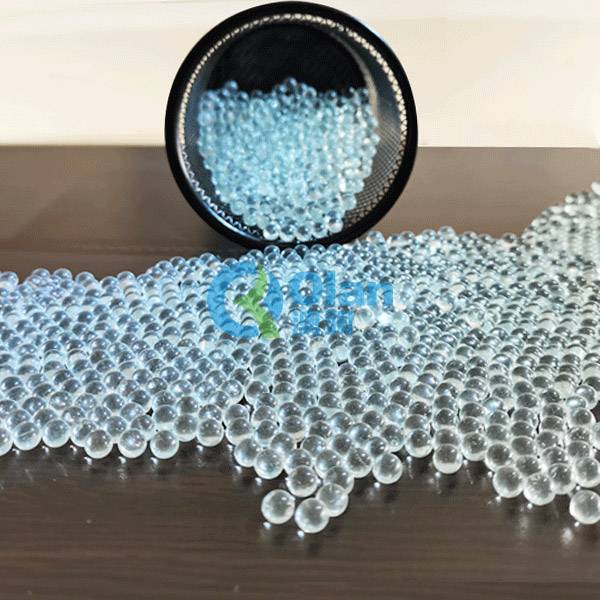

Appearance: Clean and transparent, no visible bubbles and impurity.

Density:2.4-2.6g/cm3

Hardness:6-7(Moh’s)

Spherical beads:≥75%

SiO2 content:>72%

Certificate

Packing

According to clients’ requirement.

Glass Beads used as blasting materials are with the features of clearness, hardness and toughness. They are suitable for cleaning and polishing burrs and dirt on various mold surfaces so that the processed articles have a good finish and prolong their service life. Its recyclability makes it an economical choice.The chemical nature of the glass beads is inert and non-toxic, during use, no iron or other harmful substances remain on the surface of the workpiece, nor will it adversely affect the surrounding environment. The roundness of the smooth surface makes it no scratch damage to the mechanical precision of the workpiece during the process of sandblasting. One unique application for glass bead blasting is peening, which helps the metal better resist fatigue and cracking from stress corrosion. One study found that it can increase fatigue strength by about 17.14%. It gives you an attractive satin finish while increasing the durability of the product.

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for 2020 High quality Hardness 6-7 Mohs Sandblasting Glass Beads - Sandblast Glass Beads 60# – OLAN , The product will supply to all over the world, such as: kazakhstan, Guatemala, Romania, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!